PAVEMENTS, MATERIALS, GEOTECHNOLOGY & INFRASTRUCTURE ASSESSMENT

The foundation of any soundly implemented highway project is quality materials, superb engineering, and a forward-looking maintenance strategy. Without these, even new roads can quickly fall into a state of disrepair, causing transportation agencies to shoulder immense costs to preserve their operations. KTC’s Pavements, Materials, Geotechnology, and Infrastructure Assessment group oversees a sweeping research program dedicated to improving the durability, resiliency, and service lives of roadways, highways, and bridges. Researchers work on numerous projects focused on pavement preservation, adding additives to asphalt mixes, and infrastructure assessment. The group has been at the forefront of the movement to leverage new and emerging non-destructive technologies such as LiDAR, Ground Penetrating Radar (GPR), and drone inspection. On behalf of the Kentucky Transportation Cabinet, the group has undertaken many projects that used GPR to inspect bridge decks, pavement condition, and tunnels, and they investigate how LiDAR can facilitate highway resurfacing projects and determine bridge clearance heights along busy roadways. The group has taken on numerous projects focused on selecting more appropriate pavement rehabilitation concepts through the use of a pavements forensic analysis process, collecting and utilizing more informative pavement placement temperature data during construction, and studying modifications to asphalt materials to increase pavement service life and reduce long-term maintenance costs.

featured project

Pavement Forensics and Pavement Design Technical Assistance

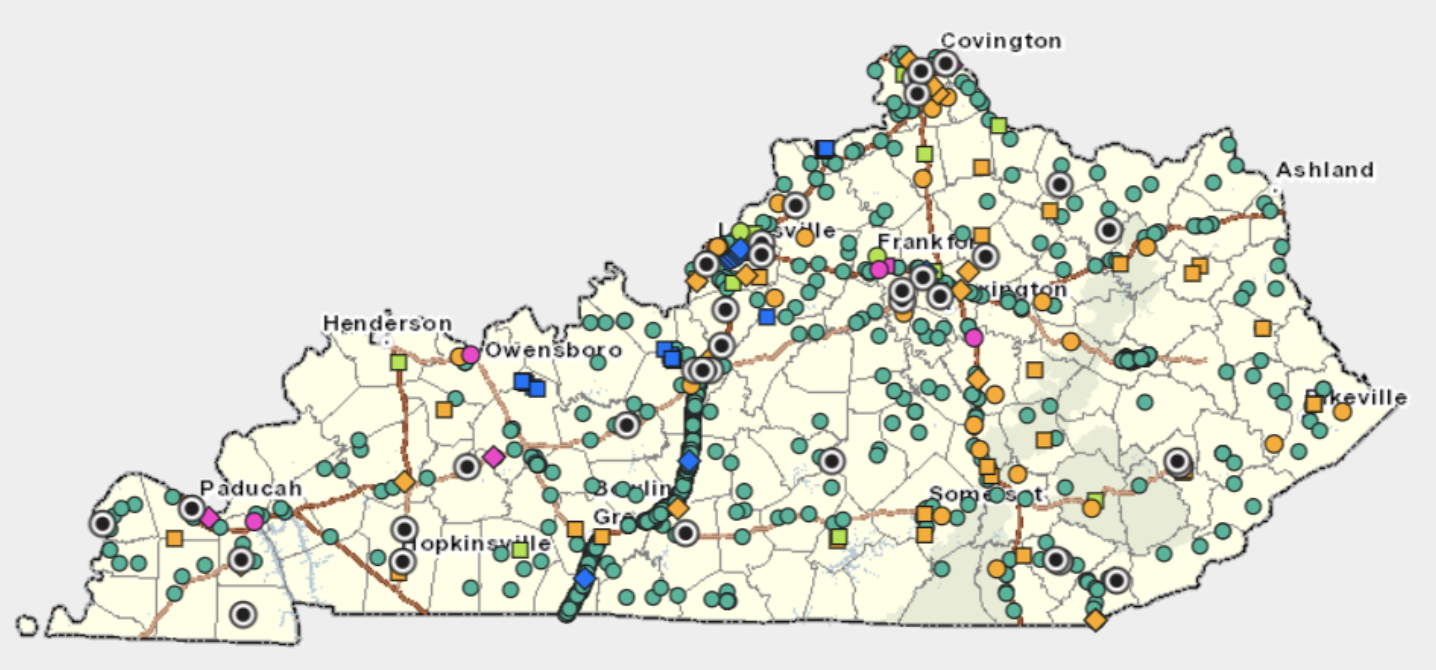

Engineers use knowledge from pavement forensic analysis to understand the structural characteristics of pavements and then prepare design and rehabilitation concepts. In 2022, KYTC awarded the Center a multiyear contract to help the agency transition the collection of pavement forensic data from a project-level activity to a planning-level activity. KTC’s comprehensive pavement forensics investigation program uses a combination of destructive and nondestructive technologies. All processed and analyzed data are maintained in an ArcGIS Online map that can be easily accessed and used by KYTC staff to decide the best way to approach pavement rehabilitation.

To offer clients real-time project results, researchers developed a secure ArcGIS project tracking database that geolocates projects, overpasses and bridges, active landslides, and other historical geologic information. When the user clicks on points on the map, a project information file opens, allowing engineering results to be delivered to the project team quickly and in the field, if needed.

RESEARCH IN PROGRESS

- KYTC Geotechnical Data Transition Support and Application Development

- Balance Mix Design Data Validation

- Correlation of Laboratory Three-Wheel Polisher Revolutions with RoadwayAccumulated-Traffic to Evaluate Laboratory Polishing of Pavements

- Evaluation of AC Binder Testing Results for Sensitivity to Kentucky Ideal-CT Test Results

- Trackless Tack Bond Strength Performance

- Development of RAP Usage Strategies

- Evaluation of Ideal-RT, HT-IDT, and Additives on Bituminous Mixture Performance

- Evaluation of Infrared Technology (Pave IR) and GPR for Uniformity Measurements During Asphalt Placement

- Forensic Analysis of Pavements Prior to Rehabilitation Decisions

Recently Completed Projects

- Stabilizing Embankment by Using Geosynthetic Reinforcement

- Current Practices in Rock Scaling

- Developing Guidelines for Evaluating Pressure on Existing Culverts under New Embankments with Buried Lightweight Materials when Highway Widening

- Merging Multiple Existing Geotechnical Databases

- Utilization of Lidar Technology — When to Use It and Why

- Non-Nuclear Methods for Compaction Control of Unbound Soil and Granular Layers

- Longer Lasting Bridge Deck Overlays

EMERGING TECHNOLOGIES

KTC researchers gather forensic analysis data on pavements, bridges and other structures with mobile test equipment. Non-destructive techniques used for forensic analysis of pavement can help design engineers make informed decisions about how to design or rehabilitate pavement structures. Compared to conventional techniques, these non-destructive methods require less time to find the solution to the problem and often prove to be more cost-efficient. Because much of the test equipment is vehicle-mounted, gathering data does not disrupt traffic and information is collected in a safer environment.

Light Detection and Ranging (LiDAR): topographically maps pavement surfaces and analyzes water flow, measures bridge and overpass heights, inventories current conditions and detects changes in bridge decks and tunnel structures.

Ground Penetrating Radar (GPR): maps the subterranean cross-section of pavement, measures the pavement layer thickness, and identifies voids and possible areas with low sub-grade strength.

Falling Weight Deflectometer (FWD): collects pavement stiffness/modulus in multiple areas along a length of pavement.

Video and Drone Inspection: diagnoses issues in pipelines, bridges, or other locations where it is unsafe for workers to inspect.

AI/Machine learning: scans stock photos of roadway networks and learns to recognize and pinpoint features such as guardrail and other highway assets.

GET IN TOUCH

PAVEMENTS, MATERIALS, GEOTECHNOLOGY & INFRASTRUCTURE ASSESSMENT FACULTY & STAFF

Kean Ashurst

Jamie Creech

Levi McIntosh

Daryl Greer

Tim Jones

Tim Scully

Charlie Sun

Senior Research Engineer

David Hacker

Research Engineer

Adrienne Beggs

Research Scientist Assistant